Destratification Fans Explained

1. Why do I need to know?

If you have a building with a large open space, such as a warehouse, hall or auditorium with a roof height of 4 metres or more then unless you have an Air Handling Unit (“AHU”) you will have stratification of the air which means all the hot air will get stuck in the roof space. If you are heating this space and you do not have destratification fans then your heating bills will be much higher than they should be?

Installing these bucket-like, variable speed destratification fans, placed strategically in large open spaces, will mix the air to provide a constant temperature and air quality.

2. How it works?

2.1. Stratification can occur

2.1.1. naturally, through solar radiation entering windows or solar gain through poorly insulated roves and wall panels.

2.1.2. via heating systems using radiators or ground level heating such as electric radiant fires

2.1.3. with the use of overhead gas radiant heaters such as black bulb types

2.2. Fig. 1 below shows a schematic of how air stratifies within a closed space, this example is within a warehouse.

Fig 1

2.3. Modern destratification fans work by pushing the hot air stuck in the roof space down to ground level as shown in Fig 2.

Fig 2

2.4. Each fan has a temperature sensor attached to the fan air intake so that the temperature of the air passing into the fan can be measured. Another sensor, or group of sensors, are installed at ground level.

2.5. BMS control

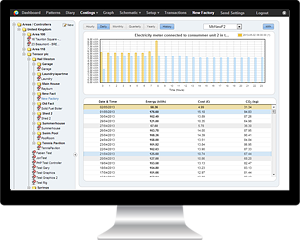

2.5.1. It’s important that a BMS system is used to control and monitor the destratification process. Here, choose a BMS system that provides minute by minute recording of temperatures so that you can use the software to visualise the destratification process.

This will enable you to trim the settings to achieve full destratification whilst at the same time blowing as air around the building as possible. Otherwise you will get complaints from employees regarding draughts and the noise of the fan. Best of course to buy low dB fans in the 1st place.

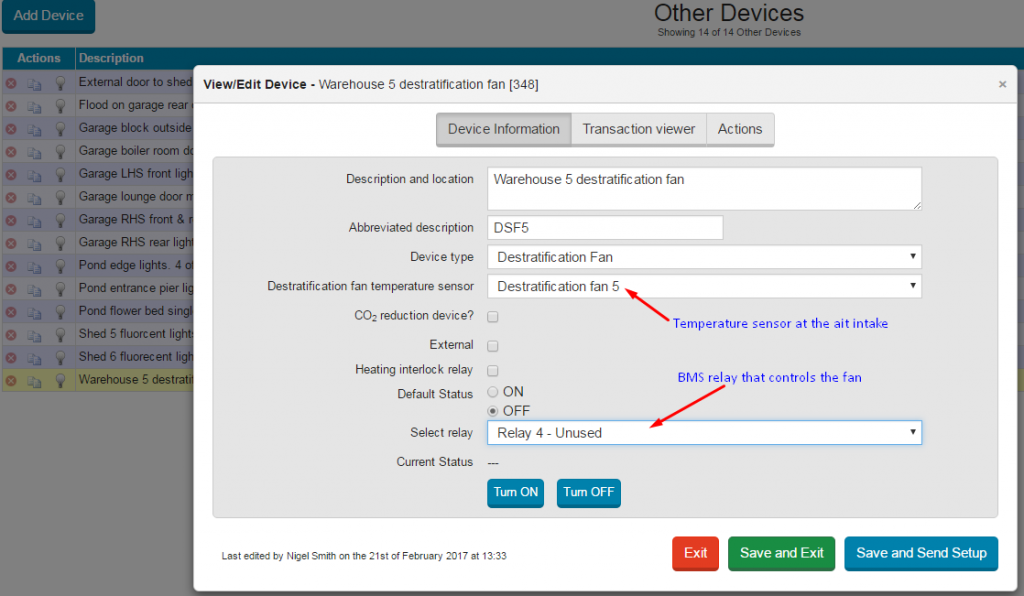

2.5.2. The typical setup and control of destratification fans using a BMS is shown below. The system will measure the temperature difference (“DeltaT”) between the fan and the ground level temperature, and then varies the fan speed depending upon DeltaT.

2.5.3. The screenshot above shows a typical fan setup on a BMS system (HeatingSave used in this example). The BMS system needs to know the temperature sensor associated with the fan and the BMS relay that controls the fan.

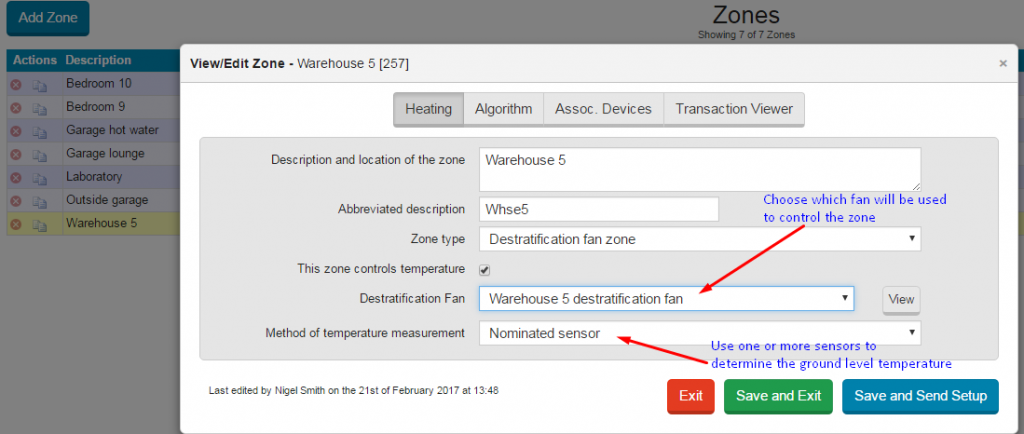

2.5.4. The BMS system will then create a destratification zone for each fan or sets of fans and assign the fan and sensors to this zone, as shown above.

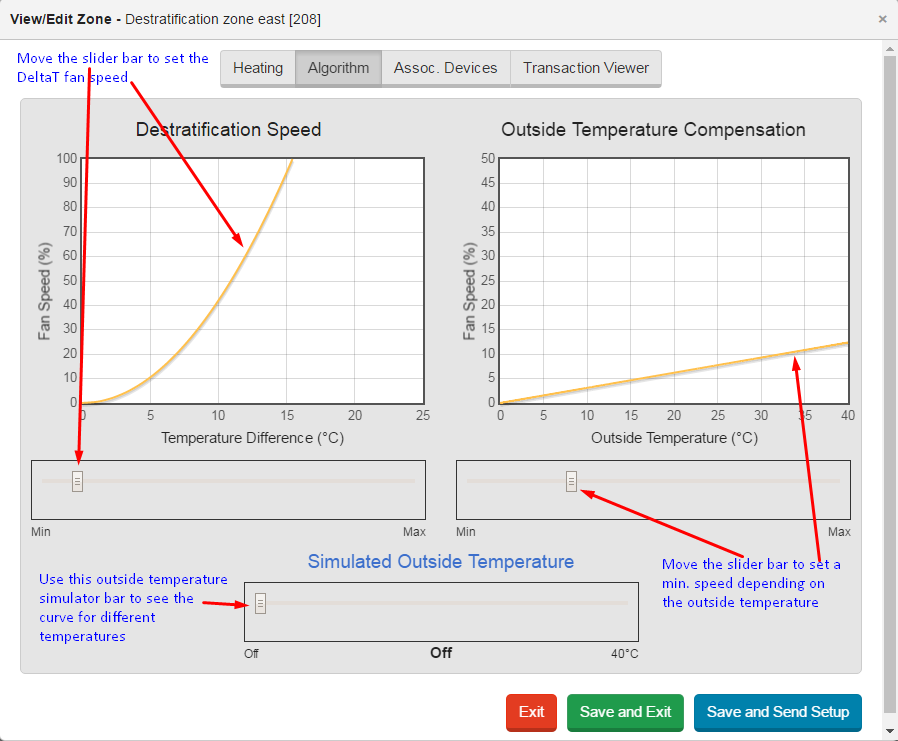

2.5.5. The BMS then allows you the trim the settings with slider bars for DeltaT and a compensation for us in hot weather to provide a minimum fan speed to cool everyone.

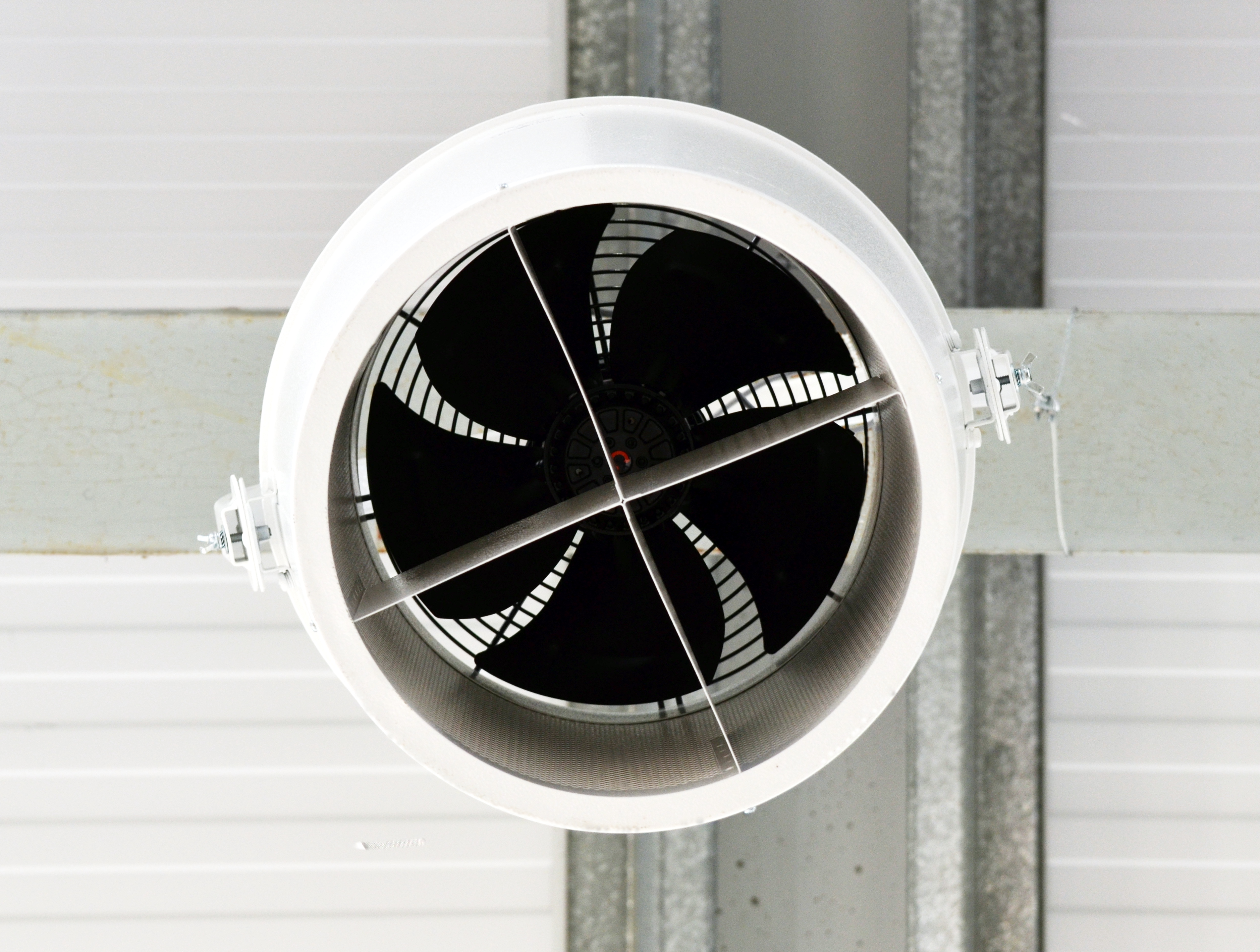

View of a low cost fan from the side View from beneath

2.6. Its best buy fans with EC motors with a 0-10 volts DC control where 0 volts turns off the fan and 10 volts is full speed; typically between 1,200 and 1,800 revolutions per minute. Fan speeds faster than this can be noisy and create an excessive downdraft. EC motors are much quieter, so always choose these in preference.

3. Show me real-world examples

3.1. The pictures below show the installation at the Coplow centre in Leicestershire.

The Coplow Centre

View of the vaulted roof with 2 destratification fans Close up view of a destratification fan

3.2. This is a large village hall/community centre with a 6 metre high hall heated with gas black bulb heater. Installing 2 destratification fans linked a BMS system (HeatingSave) cut the time to heat the hall and the energy costs by a staggering 90%. This was in part due to the building fabric which is concrete and steel and leaks heat like a sieve.

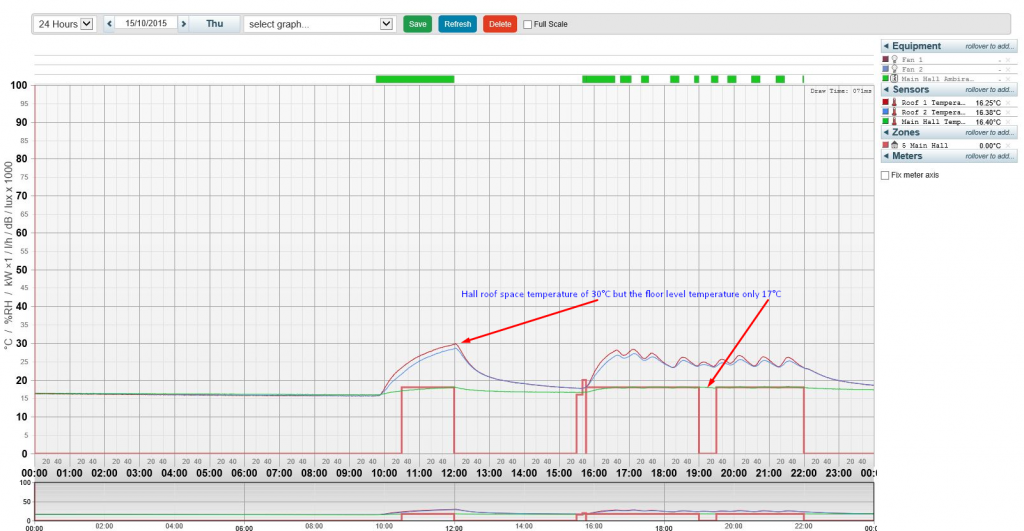

3.3. The BMS system at the Coplow centre produces temperature and energy usage data for each minute and has visualisation software so that this can be graphed. The before and after graphs below show just how effective destratification fans can be?

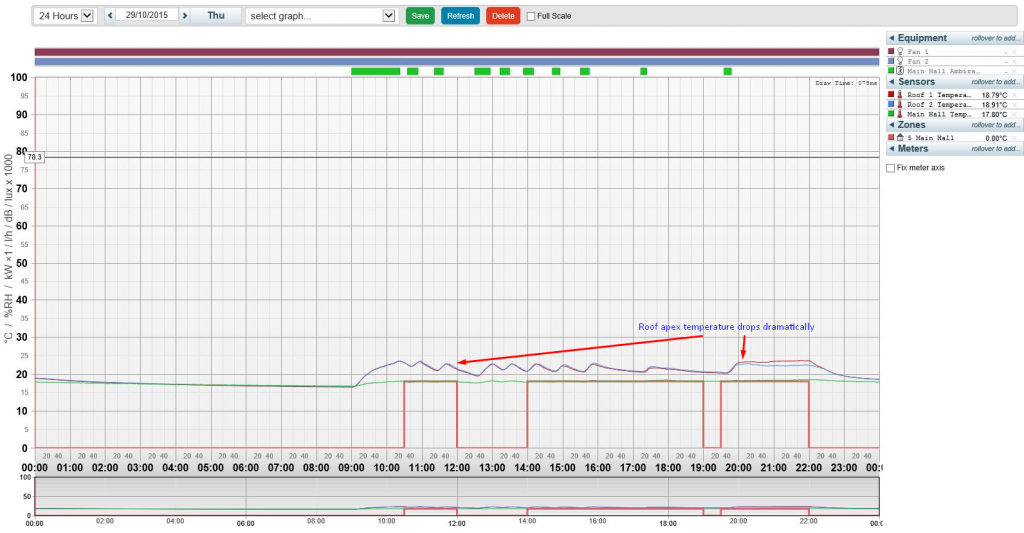

3.4. The screenshot below shows the hall apex temperatures before the HeatingSave system was installed. Note the air high temperatures in the roof space.

3.5. The screenshot below shows the hall apex temperatures after the HeatingSave system was installed. See how the difference in the roof space and the ground levels are better balanced. However, due to the poor insulation within the fabric of the building, there is still a significant difference, but this has been minimised.

Comments are closed