How to mitigate fire risks in plant and equipment by using an “early warning” system

Many pieces of plant and equipment have motors and other electromechanical devices. These devices are found in refrigerators, freezers, compressors, heat pumps (both ASHP and GSHP systems) and numerous other products, which, unfortunately, can starts to fail. This causes the equipment to draw more current leading to overheating or even fire.

Fire risks posed by households goods (such as tumble dryers or refrigerators) are not something to be overlooked, with a recent research report by consumer group Which? suggesting that fridges and freezers with flammable plastic backs currently represent nearly half the market.

Which? is also asking manufacturers to stop making such appliances, a move that follows a five-year campaign by the London Fire Brigade to have full fire-resistant backing on such appliances made compulsory.

The London Fire Brigade said it was very concerned about the current manufacturing standard, which allows flames to get through to the fridge’s insulation and accelerate a fire.

“The entire back of fridges and freezers must be properly covered in fire resistant material to limit the spread of fire, but the current manufacturing standards still allows for holes in the backing for cables or components which would leave the highly flammable insulation inside exposed,” said Dan Daly, assistant commissioner for fire safety.

“Partially covering the back of a fridge is like having a fire door with a hole in it that would allow fire, heat and smoke to pass through.”

Environmental monitoring can provide an “early warning” system for equipment malfunction

A HeatingSave monitoring system is the ideal way to provide an “early warning” of equipment malfunctions (and, indeed, fire).

It does this by constantly measuring the temperature of the equipment using stainless steel probe sensors and using this data to spot unusual rises in temperature. It also measures the ambient temperature of the environment within close proximity to the equipment as well as other airborne parameters such as volatile organic compounds, relative humidity and sound.

Together, these can indicate that all is not well?

Plastics in particular change these parameters if they are subjected to continuous and increasing low-level heat.

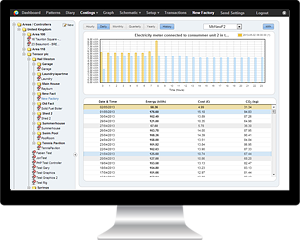

Sensor data is wirelessly transmitted to the HeatingSave T3521 hub which is connected to an Internet router. The user is then able to access the software within the T3521, via any web browser on a PC, laptop or mobile device, to set parameters and create email and Text alerts if things go wrong.

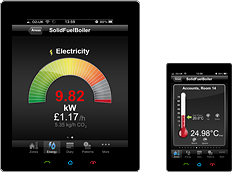

Another great feature of HeatingSave is the smart phone app that “talks” to you warning of critical conditions that require you can take immediate action. The beauty of this system is that you do not have to be at the property where the problem occurs.

Speech alerts also are particularly useful for night-time wakeup calls or for those who are visually impaired.