Shelbourne Reynolds cuts site-wide gas Space Heating costs with HeatingSave

Leave a CommentShelbourne Reynolds Engineering Ltd is a well-known British company specializing in the design and manufacture of farm machinery. The company was established back in 1972 and now operates from a 90,000 square feet factory on a 5 acre site in rural Stanton near Bury St Edmunds, Suffolk, England.

The facility currently employs 120 people and utilizes some of the most sophisticated manufacturing equipment including: CNC machine centers, laser steel cutting machines and one of the UK’s largest powder coat paint facilities.

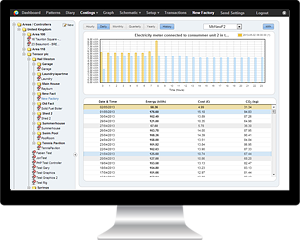

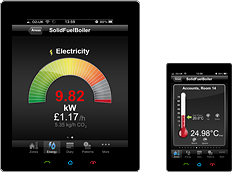

Energy costs represent a significant financial overhead for Shelbourne Reynolds. So, in 2012 the directors of the company decided to investigate what could be done to minimise the effect of ever-increasing heating and electricity bills.

“We have a very large site comprising multiple buildings, so heating costs are high. That is why we wanted a system that would help us save fuel and cut bills.” Explained Garry Bloomfield, their Procurement and Contract manager. (more…)